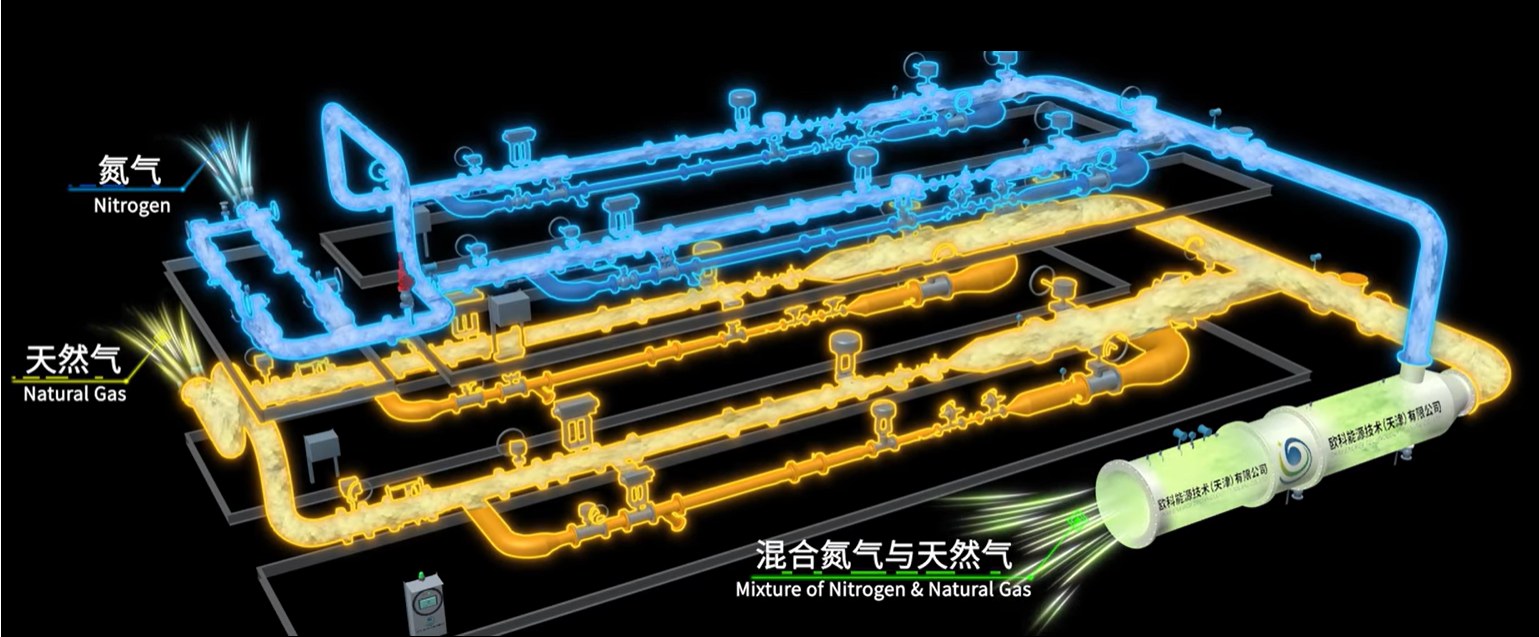

In the quest for cleaner and safer energy systems, gas blending has become a vital technology. This precise process of mixing gases to achieve a certain calorific value and composition is the basis of blending different energy sources like hydrogen and biogas into current systems. For energy operators, utilities, and industry plants, gas blending is possible, hence better system stability, higher efficiency, and future-proof operations.

The Strategic Role of Gas Blending in Energy Efficiency and Security

Modern energy systems face unprecedented complexity. With emerging renewable gases, decarbonization ambitions looming, and distributed generation in its ascendancy, maintaining a stable, reliable supply of fuel is proving challenging. Gas blending provides the flexibility to blend traditional natural gas with alternatives like:

- Hydrogen (H2)

- Biogas and biomethane

- Liquefied Petroleum Gas (LPG)

- Coalbed methane (CBM)

- Industrial by-product gases (BFG, COG, LDG)

This capability allows system operators to adaptively adjust fuel composition, adhere to pipeline standards, reach maximum combustion efficiency, and prevent supply chain disruptions—all critical to energy security and utilization efficiency.

Pipelines Standards Compliance Through Accurate Calorific Value Adjustment

The Importance of Calorific Value Consistency

Gas energy content in terms of its calorific value must be within very strict bounds to ensure the safety of pipeline transmission and safe running on final-use appliances. Any divergence results in equipment failure, incomplete burning, and regulatory non-compliance.

How Gas Blending Guarantees Standardization

By combining high-calorific gases (e.g., LNG or LPG) with low-energy gases (e.g., air or nitrogen), operators can regulate the blend to meet specific pipeline requirements. Advanced systems utilize real-time measurement and fully automatic control loops to guarantee consistent quality despite input fluctuations.

Precision Control Solutions from Okay Energy

Our Calorific Value Control Systems are precision- and reliability-engineered for a variety of applications:

- Supported Gases: Natural gas, LPG, air, nitrogen, CBM, BFG, COG, and others.

- Industry-Leading Precision: Hits blending ratios with ±1% precision.

- Adaptable Design: Dynamic flow-proportional blending customizable to specific process requirements.

- Proven at Scale: Demonstrated successfully on big projects. Such as 150,000 Nm³/h heat recovery unit for Shanxi Gas Group; 210,000 Nm³/h blast furnace gas blending for Aosen Steel.

Enabling the Future of Fuel: Synthetic Natural Gas (SNG) Production

SNG’s Role in Decarbonization

Synthetic Natural Gas from a renewable feedstock or LPG-air mix offers a carbon-neutral pathway to leverage current gas infrastructures and complement emissions abatement goals.

Blending’s Key to SNG Production

SNG production of pipeline quality requires accurate gas composition. Blending technology imparts the end product with properties and energy content that are the same as traditional natural gas.

Okay Energy’s SNG Production Experience

Our machinery enables efficient SNG production with:

- Turnkey Solutions: Design to commissioning for SNG projects.

- Precision Blending: Accurate LPG-air blending in various capacities.

- Customizable Configurations: Flexible designs for specific feedstock and output requirements.

- Proven Performance: 6,000 Nm³/h system for Pake Steel Mill operating at 0.2MPa.

Maximizing Combustion Efficiency and Minimizing Emissions

How Fuel Composition Affects Performance

The ratio of combustible content to inert gases has a direct impact on combustion efficiency. Ineffective mixtures cause energy loss, excessive emissions, and equipment wear.

Advantages of Optimized Gas Mixtures

Properly mixed gases offer:

- Improved Thermal Efficiency: More energy output from less fuel.

- Reduced Emissions: Significantly reduced NOX and CO emissions.

- Stable Combustion: Consistent performance across operating ranges.

- Extended Equipment Life: Reduced maintenance and downtime.

Okay Energy’s Combustion Technology Innovation

Our Natural Gas-Hydrogen Blending System is leading-edge clean combustion technology:

- Wide Hydrogen Range: 10%–90% blending ratios supported.

- Excellent Uniformity: 99% blending consistency achieved.

- High-Precision Control: Maintains ±1% accuracy up to a flow rate of 10,000 Nm³/h.

- Verified Performance: Successfully tested with Zhejiang Energy Group on 1.5MW turbine platforms.

Ensures Supply Stability and System Reliability

Challenges of Diverse Gas Sources

Energies are increasingly being supplied from multiple sources—LNG terminals, biogas plants, industrial by-product streams—each with varying composition and pressure characteristics.

Gas Blending for Quality and Pressure Regulation

Integrated blending systems with automatic controls and real-time monitoring provide consistent output quality independent of input variations. This ensures downstream equipment is supplied with gas of uniform composition and pressure.

Okay Energy’s Stable Integration Solutions

Our solutions ensure stable operation under diverse conditions:

- Modular Design: Skid-mounted solutions for easy deployment and scalability.

- Wide Operating Range: Flow rates from 100–200,000 Nm³/h with pressures from 0.01–2MPa.

- Comprehensive Control: Integrated filtering, pressure regulation, and real-time monitoring.

- Established Reliability: Integrated systems with PLC controls, sensor networks, and fail-safe operation.

Advanced Gas Blending Solutions of Okay Energy: Precision and Innovation

We don’t merely provide equipment at Okay Energy Technology—we provide total gas processing solutions that address today’s energy demands while gearing up for tomorrow’s opportunities.

Our one-stop solution

- Customized Design: Solutions for particular project requirements

- Precision Manufacturing: Carefully crafted equipment for safe operation

- Full Implementation: Installation, commissioning, and training services

- Support and Maintenance: Round-the-clock after-sales support and technical assistance

Tested Across Industries

Our gas utilization systems are used across various industries, such as:

- Power generation facilities

- Steel mills and metal processing

- Coal mining and coalbed methane activities

- Urban gas distribution systems

- Renewable energy integration schemes

FAQ

Q: Which gases can be mixed using your systems?

A: Our systems are compatible with almost all standard industrial and energy gases, including natural gas, LPG, air, nitrogen, coalbed methane (CBM), blast furnace gas (BFG), coke oven gas (COG), converter gas (LDG), and producer gas. We are able to configure systems for specific blends of gases.

Q: Do your systems support hydrogen-natural gas blending?

A: Without hesitation. Our Hydrogen Utilization System allows blending ratios from 5% to 90% hydrogen content based on application requirements and safety considerations. Such systems are designed with enhanced safety features and high-precision controls specific to hydrogen applications.

Q: How do you ensure blending accuracy?

A: We employ state-of-the-art real-time monitoring and control technologies, including:

- Continuous composition analysis

- Precision flow metering

- Automated PLC control systems

- Pressure and temperature compensation

This ensures uniform calorific value and composition within ±1% accuracy.

Q: Do you provide installation and training services?

A: Yes, we do full turnkey services, including solution design, equipment fabrication, on-site installation, system commissioning, and complete operator training. We ensure that your personnel are properly trained to operate and maintain the system effectively.