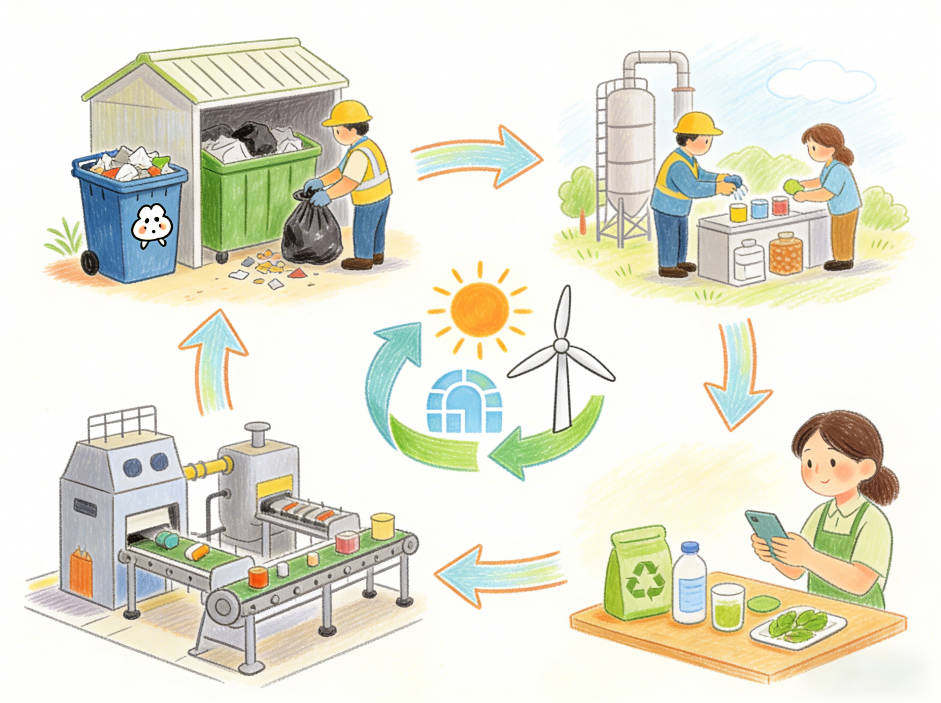

What is a Circular Economy?

In today’s resource-constrained world, the circular economy approach has gained prominence as a more sustainable alternative to the traditional linear ‘take-make-dispose’ model. This approach stresses the ongoing use of resources. It does this by cutting down waste, restoring natural systems, and keeping materials in play for the longest time possible. Instead of seeing waste as a final item, the circular economy views it as a useful resource. That resource can be reclaimed and used again.

How Gasification Fits the Circular Model

Gasification matches the ideas of a circular economy very well. It lets factories and local governments pull energy from items that would normally get thrown away. This method not only reduces reliance on landfills but also substitutes conventional fossil fuels by producing syngas—a versatile fuel derived from waste materials.

Understanding Gasification Technology

What is Gasification?

Gasification is a heat-based chemical method that changes organic or carbon-rich materials into syngas. Syngas is a blend of hydrogen, carbon monoxide, and methane. Unlike conventional combustion, gasification occurs under limited oxygen conditions, preventing complete oxidation and significantly reducing harmful emissions. Gasification relies on low oxygen levels to turn waste into syngas. This creates far less dirt in the air than burning does.

Types of Waste That Can Be Used

Gasification is a bendable method that can handle many waste types. Usual feeds include:

- Biomass: like wood chips, farm leftovers, and other plant-based stuff.

- Plastics: from hard-to-recycle packs and factory plastic bits.

- Municipal solid waste: bits like food waste, paper, and cloth.

They can process various industrial wastes, including biomass, plastics, rubber, and municipal solid waste.

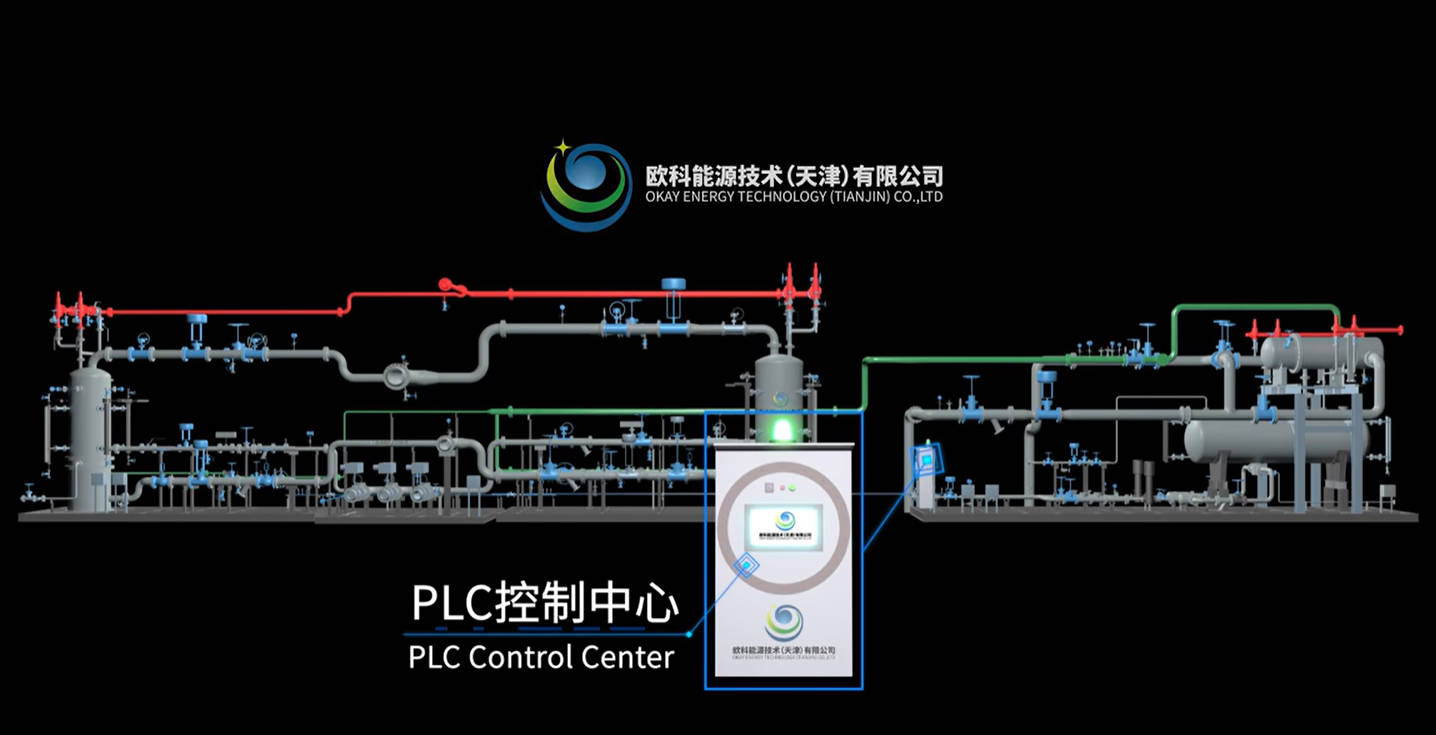

Structure of Okay Energy’s gasification Systems

At Okay Energy, our gasification setups are built with a strong focus on efficiency and safety. Our machines use smart reactor shapes that hit the best change rates. Each setup includes control tools like PLC-based monitoring, emergency stop valves, pressure controls, and easy-link pipes.

Take our LPG vaporization skid-mounted systems, for example. They mix vaporizer parts with air-powered or electric switch valves and PLC controls. This setup keeps both work quality and safety high. Skid-mounted vaporizers are built-in, ready-to-move systems meant to shift Olefin items like LPG from liquid to gas form quickly, safely, and up to work rules. We’ve seen these in action at sites where quick setup cuts downtime by days, based on feedback from over 50 installs in the past five years.

From Waste to Energy Products

Producing Syngas from Waste

The main result of gasification is syngas. This is a fuel-packed gas made of hydrogen (H₂), carbon monoxide (CO), and methane (CH₄). Syngas can be combusted directly as a fuel or used as a feedstock for producing chemicals and synthetic fuels. Thanks to our special setups, syngas gets cleaned and readied safely for more steps.

Generating Electricity and Heat

After making it, syngas can drive gas turbines or motors to make electricity. The warmth from this step can be grabbed through heat recovery tools. Then, it’s used for area heating or factory needs. Our Integrated LPG Storage & Vaporization Units, as implemented at CNOOC and China Resources (CR), demonstrate the effective use of vaporized LPG for boiler ignition and heating.

- Product Name: Integrated LPG Storage&Vaporization Unit

- Application: Flare&boiler ignition gas supply system

- Heating method: Electric-water-bath.

One power plant using this cut startup time from hours to minutes, based on logs from similar sites handling up to 500 starts per year.

Gasification’s range makes it great for many fields:

- Manufacturing plants use it to make their own power from factory waste.

- Municipalities gain by shrinking landfill use while making electricity for city services.

- Power plants rely on strong start systems backed by our Integrated LPG Vaporization Units.

Benefits for Businesses and the Environment

Lowering Operational Costs

With gasification tools, companies can drop their running costs by a significant amount. It reduces the need to buy outside energy. Plus, it trims waste removal bills. Scalable options like our LPG vaporization skid-mounted system, with gas-turning rates from 1,000kg/h(Electric heating) to 60,000kg/h(steam-heated), let places pick setups that fit their power needs just right.

Environmental Impact Reduction

Traditional waste management methods, such as landfilling or incineration, contribute significantly to greenhouse gas emissions and generate hazardous residues. Gasification gives a cleaner choice. It turns waste into useful fuel with way fewer releases. It changes waste into workable energy or items. This cuts the pull on fresh supplies and lessens harm to nature. On top of that, Okay Energy sticks to green progress. We keep researching to cut releases more with better setup designs.

Creating New Value Streams

In addition to energy production, gasification generates valuable by-products. For example, ash from biomass can be utilized in cement or construction, and surplus energy can be fed into the power grid to generate additional revenue. Blended gases can raise heat value with tools like our Calorific Value Control System. This keeps output steady and strong. An integrated solution designed to precisely mix multiple natural gas streams to achieve optimal composition for end-use applications.

Why Choose Okay Energy Solutions?

Proven Technology and Expertise

With more than ten years in energy work, Okay Energy stands as a reliable source of factory gas gear in world markets. We blend three main areas—energy tech research, top-level gear making, and build services—to hand out fresh energy fixes everywhere. Our work includes ties with big names like Petro-China, Sinopec, CNOOC, and Pacific Energy. Over 200 projects show our track record, from small pilots to full plants serving 1 million households.

Reliable Support and Maintenance Services

Our after-sales group covers the globe with round-the-clock quick help. From tech talks to site setups and worker training, we make sure clients get fast aid throughout the gear’s life. Explore the market’s most comprehensive range of industrial gases and mixtures in everything from industrial grade to ultra-high purities.

Commitment to Sustainability Innovation

At Okay Energy, green goals push our new ideas. We keep improving our goods to get the most work out and cut nature’s harm. This happens through better heat swap parts or sharper auto controls with PLC units. Aligned with our vision of long-term sustainable energy solutions, Okay Energy collaborates with global partners to advance efficient and low-emission technologies.

FAQ

Q: What types of waste can Okay Energy’s gasification systems handle?

A: They can process various industrial wastes, including biomass, plastics, rubber, and municipal solid waste.

Q: How is gasification different from incineration?

A: Gasification uses low oxygen conditions to convert waste into syngas, producing less pollution than incineration.

Q: Can small factories use Okay Energy’s technology?

A: Yes, solutions are scalable and can be customized based on the factory’s size and waste output.

Q: Is the syngas safe to use?

A: Yes, when properly treated through Okay Energy’s systems, syngas is safe for electricity generation or heating.

Q: How does this technology support a circular economy?

A: It transforms waste into usable energy or materials, reducing reliance on raw resources and minimizing environmental impact.