LNG Price Volatility and Manufacturing Challenges

Changes in LNG (Liquefied Natural Gas) prices now pose a real problem for manufacturers around the world. Energy expenses make up a large part of running costs. So, when LNG prices swing wildly, they throw off plans for production expenses and future budgets. Things like political unrest in key areas, breaks in supply lines, sudden jumps in demand during certain seasons, and shifting costs for shipping add to this lack of steadiness.

Such unpredictability pushes manufacturers to seek out dependable and affordable fuel options. Gasification methods, especially those combined with modern gas mixing setups, serve as a practical way to handle swings in energy prices. Okay Energy provides detailed LPG gasification and fuel blending systems. These let manufacturers swap out LNG for LPG in a managed and effective way.

Understanding LNG Price Volatility

Causes of LNG Market Fluctuations

LNG prices react strongly to various outside influences:

- Geopolitical tensions: Conflicts in major energy-producing regions often lead to supply disruptions.

- Seasonal demand: LNG prices typically spike during winter months in Asia and Europe.

- Currency exchange rates and transportation costs: Given the international nature of LNG trading, fluctuations in exchange rates and freight charges directly affect contract prices.

All these elements build a shaky market. In turn, planning energy costs becomes tough for factories and other big users.

Impact on Manufacturing Operations

Unstable LNG prices affect manufacturers in the following ways:

- Budgeting and forecasting lose reliability, leading to reactive financial strategies.

- Production costs rise unexpectedly, eroding profit margins.

- Price-sensitive industries face a competitive disadvantage when energy expenses cannot be controlled.

LPG as an Alternative Fuel Source

Cost Comparison: LNG vs LPG

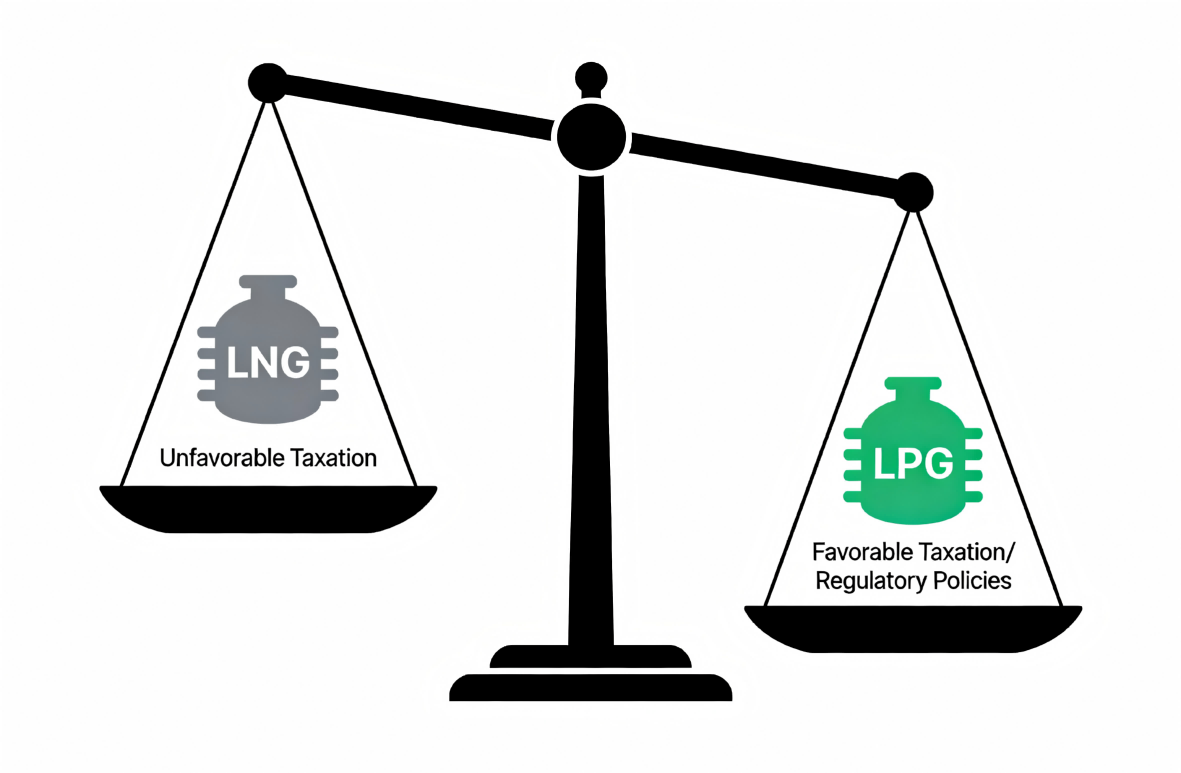

Past records show that LPG prices stay more even than those of LNG. On top of that:

- LPG logistics involve less complex infrastructure than LNG’s cryogenic requirements, resulting in lower transportation and storage costs.

- In many countries, LPG benefits from favorable taxation or regulatory policies, further enhancing its cost-effectiveness.

Availability and Scalability of LPG Supply

LPG comes from worldwide operations as a byproduct of refining oil and processing natural gas. Because of this broad output, it stays readily available. Plus, its easier storage and handling turns it into a practical choice for factory use. Factories don’t need huge cryogenic setups for it. For example, refineries in the Middle East produce millions of tons of LPG yearly. This steady flow supports industries scaling up without supply worries, unlike LNG’s tighter chains.

Okay Energy’s Gasification Solution

Overview of Okay Energy Equipment Technology

Our company focuses on modular skid-mounted gasification systems. These fit right into factory workflows. Items like the Integrated LPG Vaporization Unit handle outputs from 100kg/h to 25,000kg/h, matched to specific needs. You can get them in electric-water bath, steam-heated, or hot water styles.

Take the LPG vaporization skid-mounted system, for one. It uses steam-heated vaporizers. The design allows transport by road, and it has quick-connect piping for easy setup.

High-Efficiency Gas Blending Capabilities

Okay Energy Systems stands out in on-the-spot gas blending. The Calorific Value Control System works with materials like LPG, air, nitrogen, and natural gas. Flow rates go from 5,000Nm³/h to 210,000Nm³/h. This setup allows for:

- Automated blending for consistent fuel heating value.

- Real-time performance optimization through PLC control systems.

- Precise control of fuel heating value for production by an automated blending system.

Integration with Existing Infrastructure

Our systems come built for easy matching:

- Quick-connect piping (DN50 flanges) or adjustable according to user requirements.

- Minimal retrofit requirements for existing burner setups.

- Skid-mounted designs reduce installation time and civil work.

These traits simplify adding them to ongoing factory sites. Costs stay low, and setup happens fast.

Economic Benefits of Switching to Gasification

Fuel Cost Savings Analysis

Short-Term Operational Savings

When factories move to LPG using gasification:

- Per-unit energy costs are significantly reduced.

- Maintenance needs decline due to cleaner combustion characteristics associated with LPG compared to LNG.

Right away, this cuts daily fuel bills. LPG burns with fewer residues, so equipment lasts longer.

Long-Term Investment Return

Okay Energy’s clients typically achieve ROI within 6–18 months. The modular design allows phased implementation, enabling scalable adoption based on plant size. Predictable long-term energy pricing aids in strategic business planning and margin protection. For larger plants, full payback often hits around 12 months. Smaller ones see it sooner, in 6 to 9 months. This comes from steady LPG rates versus LNG’s ups and downs.

Enhancing Manufacturing Competitiveness

Steady fuel supply brings better money forecasts. It lowers risks from the shaky global gas trade. With fixed costs, factories plan without surprises.

Strengthened Market Position

By reducing energy costs, manufacturers can improve production efficiency and strengthen their market position. Lower production costs empower manufacturers to compete more aggressively on price or invest savings into other strategic areas such as R&D or expansion. This edge helps in tough markets.

Implementation Strategy for Manufacturers

Assessing Energy Needs and Consumption Patterns

Starting the change means a full check of the present fuel use. Our engineers look at load patterns, changes by season, and high-demand times. They figure out if the switch works well. This audit often reveals peaks, like a rise in winter for heating-heavy plants. Based on that, we tailor plans to match real daily flows.

Customizing a Gasification Plan with Okay Energy

Site-Specific System Design

Every system gets built to fit the site’s scale, vaporization needs, fuel kind, and workload. For instance:

The Integrated LPG Vaporization Unit deployed at China Eastern Electric Group Co., Ltd (Bangladesh) delivers 400Nm³/h using electric-water-bath heating under 0.8Mpa pressure conditions tailored for high-energy ignition systems. In this case, the unit handled local power grids perfectly. It vaporized LPG steadily, supporting 24/7 operations without hitches.

Deployment Timeline and Support

We provide end-to-end turnkey services including scheme design, equipment production, on-site installation, personnel training, and after-sales technical support. Our fast-track deployment process ensures minimal disruption to existing operations. Typically, the full setup takes 4-8 weeks. Training covers safe handling, and support includes remote monitoring for the first year.

Conclusion

Adopting Okay Energy’s gasification technology provides manufacturers with a viable path to minimize exposure to LNG price volatility while achieving real-world fuel savings through LPG substitution. Our advanced skid-mounted solutions—featuring real-time blending control, compatibility with existing infrastructure, and proven return on investment—are designed for industrial scalability and energy security. As global markets grow more unpredictable, our technologies offer manufacturers the certainty they need to maintain cost leadership and operational efficiency.

FAQ

Q: What makes LPG a better alternative to LNG for manufacturers?

A: LPG offers more stable pricing, lower logistics costs due to simpler storage requirements, and is often subject to more favorable taxation policies compared to LNG.

Q: How does gasifier help reduce fuel costs?

A: Our systems enable precise gas-air blending using automated control systems that ensure optimal combustion efficiency and fuel usage.

Q: Can I integrate Okay Energy equipment into my existing plant?

A: Yes. Our skid-mounted units feature quick-connect interfaces and are engineered for compatibility with standard industrial infrastructure.

Q: How quickly can I see ROI after switching to gasification?

A: Most clients report full ROI within 6–18 months, depending on usage scale and fuel cost differential between LNG and LPG.

Q: Is it safe to operate a gasifier system in a manufacturing environment?

A: Absolutely. All systems include multiple safety layers such as automated shut-off valves, leak detection sensors, and PLC-based emergency protocols tailored for industrial use.