Importance of Safety in LPG Vaporization

Industrial LPG vaporization systems play a key role in various large-scale operations. These include petrochemical plants, power generation facilities, and fuel gas supply networks. Yet, the basic properties of liquefied petroleum gas make it highly flammable. It is also stored under significant pressure. This creates real dangers if safety measures are not strictly followed. Such risks involve overpressure events, gas leaks, flashbacks, and thermal overloads. All of these can result in severe consequences for workers and machinery alike.

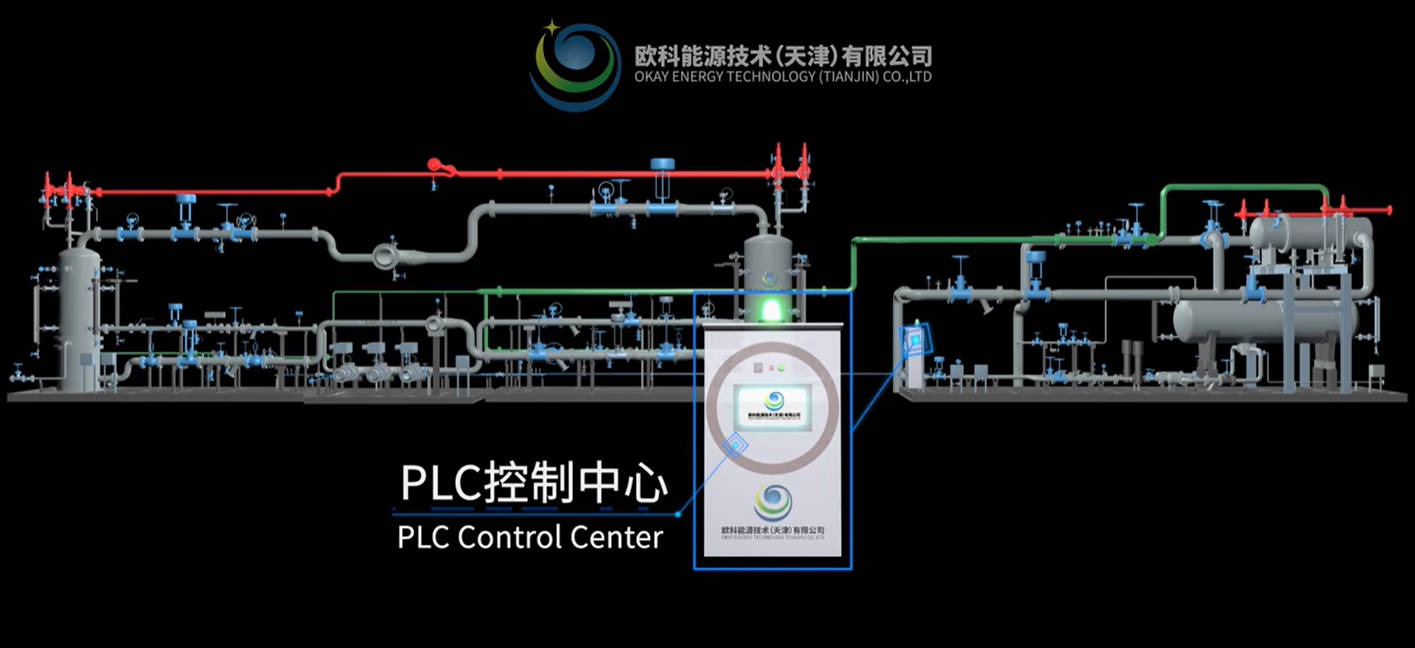

As a top supplier of LPG vaporization systems, Okay Energy delivers practical, secure, and tailored gasification options for vital chemical materials like LPG (liquefied petroleum gas), propane, propylene, and ethylene. Protecting safety goes beyond just safeguarding equipment. It forms the base for steady operations and meeting global safety rules.

Overview of Critical Safety Features

Spotting key safety parts in LPG vaporization gear is vital for cutting down risks. It also helps follow industrial rules. Below, we outline five basic safety elements. Any solid industrial-grade LPG vaporization system must include them. This keeps operations running smoothly and shields workers.

Automatic Pressure Relief System

Role in Overpressure Protection

Overpressure situations might arise from faulty regulators, clogged outlets, or heat expansion. An automatic pressure relief system counters this danger. The automatic pressure relief system releases excess pressure through a controlled valve mechanism, preventing damage to components and mitigating the risk of system failure. As a result, this prevents component failure and reduces the risk of uncontrolled gas leaks.

Design Integration in Okay Energy Devices

Our systems are built to adhere to global safety standards, including ASME and ISO certifications, ensuring the highest level of reliability and compliance in industrial settings. These can manage working pressures from 0.2Mpa to 3.0Mpa, based on the setup. In our LPG vaporization skid-mounted system, we fit spring-loaded or pilot-operated relief valves. They react fast to sudden pressure rises. The materials for these safety parts meet codes like ASME and ISO9001/14001 certifications. This guarantees they last and work well in tough, high-pressure settings.

Leak Detection and Monitoring System

Continuous Gas Leak Surveillance

Small leaks in an LPG setup can build up over time. They might create explosive mixes in tight spaces. For this reason, ongoing leak checks are essential. Modern sensors in the vaporization unit keep watch on hydrocarbon levels all the time. They set off alarms if limits are crossed.

Okay Energy’s Sensor Technology

Fitted with a fully automatic PLC/DCS control module, our systems track gasification output, temperature, and pressure in real time. They also allow remote handling and upkeep. Okay Energy units use infrared or catalytic bead sensors for sharp detection. Built-in alarm setups are set to send warnings. They can also start automatic actions, such as closing valves or stopping the system.

Emergency Shut-Off Mechanism

Function During Critical Failures

An emergency shut-off setup is key for cutting off gas flow in case of breakdowns, leaks, or fire threats. This feature lets operators—or the system on its own—stop everything right away. It helps keep problems from growing worse in urgent situations.

How Okay Energy Implements Shut-Off Systems

Within our Integrated LPG Storage & Vaporization Unit, we add pneumatic or electric actuated emergency shut-off valves. These link to the main PLC control setup. Operators can trigger them from afar, or they activate on their own from sensor data. The overall structure has backup plans. This means shut-off works even if power fails or sensors glitch.

Flame Arrestor Integration

Preventing Flashback Hazards

Flashbacks happen when flames move back through the gas pipe. This brings a major explosion threat. Flame arrestors work to put out flames. They do this by spreading heat across fine mesh or twisted ribbon parts. This stops the fire from moving upstream.

Flame Arrestor Design by Okay Energy

We apply rust-proof stainless steel flame arrestor parts. They carry certifications from global standards. This supports reliable use in tough industrial spots. These prove crucial when vaporized gas feeds into ignition setups or hot areas, such as boilers and furnaces. Our 100kg/h electric-water-bath vaporizer units serve these needs for customers like CNOOC.

Overheat Protection System

Safeguarding Against Thermal Runaway

Thermal runaway starts when the heating part gets too hot. This might come from control issues or too much demand. It could harm the system or spark fires. Overheat protection makes sure heating stops if temperatures go beyond set points.

Thermal Control in Okay Energy Equipment

Precise temperature sensors work with programmable logic controllers (PLC) as standard in all Okay Energy units. Take our Electric-water-bath LPG vaporizer, for instance. It keeps the temperature steady via multi-layer insulation and thermal cut-off switches. This delivers even results despite changing workloads.

Conclusion

Safety stands as the main pillar for all industrial LPG vaporization tasks. Each element we covered—pressure relief systems, leak detection, emergency shut-offs, flame arrestors, and overheat protection—acts as a strong barrier against major breakdowns. By adding these protections to every piece, Okay Energy shows its dedication to dependability. We also stick to strict safety guidelines in making industrial gas tools.

Items like our LPG vaporization skid-mounted system (1000kg/h – 6000kg/h) and the Integrated LPG Storage & Vaporization Unit provide easy setup. They come as factory-checked modular parts for quick on-site joining and fast startup. These focus on both strong performance and safety in demanding settings.

FAQ

Q: What are the main risks associated with LPG vaporization equipment?

A: Key risks include overpressure, gas leakage, flashbacks, overheating, and uncontrolled gas flow—all of which can lead to fire, explosion, or system failure if not properly managed.

Q: Why is an emergency shut-off system critical for LPG gasification devices?

A: It allows operators to quickly isolate the system during faults or emergencies, preventing escalation of hazardous situations.

Q: Can leak detection systems prevent all types of failures?

A: While they significantly reduce risk by identifying leaks early, they should be used in conjunction with other safety features like shut-off systems and overheat protection.