1. What Is an LNG System and How Does It Work?

Basic Elements of an LNG System

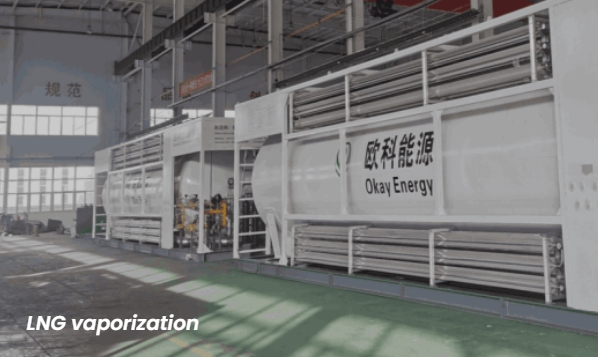

Liquefied Natural Gas (LNG) systems are sophisticated solutions that entail the conversion of natural gas into liquid form, storing it in a compact form, and ultimately revaporization it for use. The principal elements of a typical LNG system are the liquefaction unit, cryogenic tanks, vaporization or revaporization units, pressure regulating systems, and safety control systems. Vaporization units and Natural Gas Pressure Regulation & Metering systems. One-Stop Gas Processing Solutions by Okay Energy allow us to offer integrated systems developed to meet industrial energy needs.

The Process of Liquefying Natural Gas

The liquefaction process itself involves cooling natural gas to around -162°C (-260°F), where it is transformed into a clear, colorless liquid. Through the process, its volume is reduced roughly to 1/600 of its original volume, which makes it easier to economize on storage and transport. Delivered at the point of use, the LNG is then pumped through vaporization units—such as our LNG vaporization product line—safely reconstituting the liquid to a gaseous state for dispensing or burning.

Key Benefits of LNG Systems

A number of advantages are offered by LNG systems. For example, in low-density areas, laying natural gas pipelines is often cost-prohibitive and uneconomical. Pipeline installation in rugged terrain can also present technical challenges. Furthermore, when natural gas pipelines are not yet constructed, LNG systems can serve as a temporary gas supply solution, meeting local gas needs in a timely manner.Our products, such as Integrated skid-mounted equipment, is engineered to offer energy reliability to different industries.

2. Why LNG Is Superior to Other Forms of Energy?

Ecological Advantages of LNG

Maybe the most compelling reason to implement LNG is its environmental benefit. Compared to oil or coal, natural gas emits far fewer pollutants in the form of carbon dioxide (CO2), sulfur oxides (SOX), nitrogen oxides (NOX), and particulate matter. During combustion in high-tech industrial burners or engines, LNG incurs cleaner combustion along with reduced release of greenhouse gases. As part of our commitment to sustainability, Okay Energy offers cutting-edge technology like Industrial Gas Blending/Calorific Value Control and Management that enhances fuel composition for cleaner burning.

Cost Competitiveness Over Alternatives

LNG provides economic advantages where pipeline infrastructure is poor or lacking. Due to its high energy density, it is easily transported in bulk in ships or vehicles at comparably low cost per unit of energy. Furthermore, the modularity of the system—e.g., in LPG vaporization (vaporization) units—enables deploy ability to scale to meet varying demand.

Safety and Storage Considerations

Even though it is challenging to operate the cryogenic liquids, modern LNG systems incorporate more than one level of protection, such as double-wall vacuum-insulated vessels, shut-off emergency valves, leak detection probes, and pressure relief devices with automatic controls. Our equipment conforms to global specifications of industrial reliability and security.

3. How to Select the Proper LNG System?

Factors to Take into Account During System Selection

The selection of a proper LNG system is under consideration of multiple factors: required flow rate, pressure requirements, site conditions, regulatory requirements, and economic constraints. We work in close contact with customers to identify their respective needs before making suggestions from our portfolio of tailored options.

Matching System Capacity with Energy Needs

Energy demand varies significantly between industries—from compact manufacturing plants to bulk utility providers. It is for this reason that we introduce scalable products like Natural Gas Pressure Regulation & Metering stations that can be engineered for different throughput levels with continuous control over delivery factors.

Why Okay Energy Offers Uniform Solutions

At Okay Energy Technology (Tianjin) Co., Ltd., we stand out as more than a supplier—but your partner in business for energy optimization. One-Stop Gas Processing Solutions by Okay Energy means to grasp every process from design consultation through installation and after-sales service. Our team is at your service at +86 18630851982 (WeChat same number) or by email on our official website for customized proposals based on your business operations.

4. What Should You Consider for Installation and Maintenance?

Planning for Efficiency from the Start

A key consideration for any LNG project is minimizing the complexity and cost of installation and maintenance. Opting for a skid-mounted, integrated system is the most effective strategy, as it drastically reduces on-site labor, time, and potential disruptions by arriving pre-assembled and tested.

How Okay Energy Simplifies the Process

We transform this process by providing Integrated skid-mounted equipment that are ready for rapid deployment. Beyond superior equipment, we offer comprehensive support, including on-site installation guidance, professional commissioning, and complimentary remote technical support to ensure optimal long-term performance and quick issue resolution.

Securing Peace of Mind for the Future

This holistic approach guarantees that your system is not only installed correctly and efficiently but also supported throughout its entire lifecycle. Partnering with Okay Energy means investing in a solution designed for minimal hassle and maximum operational reliability, securing your energy investment for years to come.

5. How Safe Are LNG Systems When Used daily?

Safety Features Integrated in Okay Energy Systems

Our systems have multiple in-built safety features such as automatic emergency shutdowns triggered because of overpressure or leakage detection; temperature alarms; fire suppression interfaces; and anti-corrosion coatings on all exposed surfaces. These in-built features are included in all of our major product lines, such as our Cryogenic Gas vaporization systems and CNG Pressure Reducing modules.

Protocols for Handling, Transport, and Storage

Safe operation procedures involve operator training in cryogenics safety procedures; use of personal protective equipment; adherence to transport regulations on tank insulation requirements and online monitoring during unloading activities that are being performed. We also have guidebooks in accordance with worldwide best practices on all aspects, from the construction of the loading dock to spill emergency containment.

Emergency Response and Monitoring Capabilities

In the case of abnormal behavior, such as a sudden increase in pressure or unexpected temperature shift in storage tanks or pipelines, our control panels initiate automatic responses in the form of alarm signal generation and system isolation schemes. We also allow integration with SCADA-based remote monitoring systems that allow clients to monitor performance parameters in real time, as well as receive alerts on cellular phones in the case of thresholds being breached.

FAQ

Q: Which industries can avail the benefits of using LNG systems?

A: Factory industries, power plants, mining plants, food factories, vehicle fleets running LNG vehicles—all benefit from guaranteed access to clean-burning fuel with our tailor-made solutions such as Natural Gas Pressure Regulation & Metering stations or LPG vaporization Units.

Q: Can I get my system designed according to my site layout?

A: Yes! All our products are in modular form, which allows flexibility in configurations based on space constraints or expansion plans.

Q: Do you ship internationally?

A: Absolutely—we ship internationally through coordinated logistics partners to ensure timely delivery regardless of where you are.

Q: How often should I schedule maintenance checks?

A: We recommend quarterly checks with annual full-system diagnostics depending on usage frequency—step-by-step instructions are provided with ordering.