Gasification in Industrial Energy Systems

Gasification holds a key spot in today’s industrial energy setups. It turns carbon-based materials into synthesis gas, or syngas. This gas works well for heating, making power, or serving as a base for chemicals. The method gives choices in picking fuels. Industries can draw from options like natural gas and oil to handle their energy needs in a practical way. Choosing the right gasification source affects the end product’s quality a lot. It also shapes how well the system runs, how much money goes into building it, and the day-to-day running costs.

Why Compare Natural Gas and Oil Gasification

Natural gas and oil stand out as easy-to-get and common fuels in factories. Yet, their gasification steps vary in clear ways. These include what goes in, how complicated the machines are, and what extra stuff comes out. Knowing these gaps matters for businesses that want to fine-tune their energy plans. They aim to cut down on waste gases and keep costs in check. As a full-service energy provider, Okay Energy supplies custom gear setups for gasification using either natural gas or oil. These fit a range of work situations.

Gasification Principles

Basic Process Overview

Gasification refers to the partial oxidation of hydrocarbon fuels under controlled conditions. Here, full burning doesn’t happen. Instead, it creates syngas. This mix mainly includes hydrogen (H₂), carbon monoxide (CO), and carbon dioxide (CO₂). The makeup of syngas changes based on the starting material and the exact way it’s done.

Natural Gas Gasification Basics

Natural gas gasification mainly acts as a reforming step. Methane (CH₄) mixes with steam or oxygen at very high temperatures. Catalysts help out too. This leads to syngas that’s rich in hydrogen. The process stays cleaner and simpler than with thicker fuels. As a result, the syngas has fewer unwanted bits.

Oil Gasification Basics

Oil gasification, on the other hand, deals with breaking down and burning heavy hydrocarbons through heat. It often needs strong pressure. Oxygen or steam is introduced into the reactor. The syngas that comes out has more carbon monoxide. So, cleaning it up takes more work.

Output Characteristics Comparison

Syngas Composition Differences

Syngas from natural gas shows high levels of hydrogen. It forms little tar because the molecules are basic. Oil-based syngas, by contrast, holds more CO. Plus, it picks up more dirt like sulfur bits, soot, and tars. Additional purification steps are required prior to utilization. For example, in a steel plant, natural gas syngas might need just basic filtering, while oil versions could require scrubbers to remove sulfur.

Byproducts and Emissions

Gasification with natural gas cuts down on bad waste gases and excesses. It keeps sulfur oxides (SOx), dust particles, and carbon dioxide (CO₂) at low points. Oil systems, however, often make slag, ash, and more CO₂. This results from the complex composition of the fuel.

Equipment and System Requirements

System Design Considerations

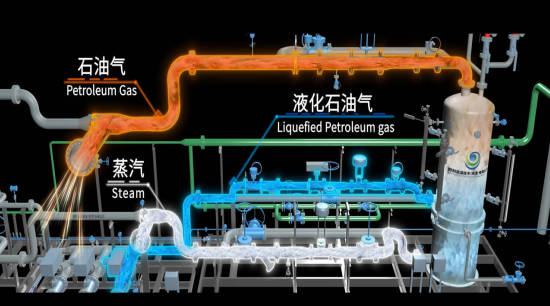

Okay Energy builds gasification systems that handle both natural gas and oil feeds. We use modular, easy-to-move platforms on skids. Take the Integrated LPG Storage & Vaporization Unit, for instance. It’s a small unit that packs in cold storage, air-based vaporizing, pressure control, flow measuring, and PLC oversight. This suits natural gas jobs perfectly. Such setups tend to be compact and simple to set up, unlike those for oil.

Maintenance and Operational Demands

Systems for oil face tougher byproducts that eat at parts and run hotter. So, they need strong materials and regular check-ups. Natural gas setups dodge most fouling and rust issues. This means less time stopped and a longer life for the gear. Okay Energy’s LNG Satellite Station, with its ready-to-go modules, cuts down on building work at the site. It keeps things steady in factory settings.

Efficiency and Economic Factors

Energy Conversion Efficiency

Natural gas gives better heat output thanks to its straightforward burning. The methane focus yields more hydrogen with less effort put in. Oil gasification can work well in big operations, like at refineries. But in smaller or spread-out spots, it lags because handling the fuel gets tricky.

Capital and Operating Costs

Natural gas systems typically require lower capital expenditure (CAPEX) due to modular design. Modular designs skip big groundwork. Oil setups demand more cash for prepping the fuel, controlling waste gases, and handling materials that stand up to wear. Running costs climb too, from dealing with slag and cleaning syngas.

Application Scenarios Analysis

Use in Power Generation

Power plants with combined cycles often pick natural gas for its strong output and small emission footprint. Okay Energy delivered cryogenic vaporizers like the 200m³ LNG Peak Shaving Plant to groups such as Zhengmao Gas Group. This helps steady the grid during high-use times. Oil gasification fits where pipelines are missing or heavy oil is on hand.

Use in Industrial Heating

Natural gas and oil both meet the needs for high-heat jobs. The choice hinges on fuel access, local rules on emissions, and how the system is built. In far-off spots rich in oil, these systems go in with added filters and cleaners to hit standards.

Decision-Making Guidelines

Fuel Availability Assessment

Getting fuel to the site shapes the tech pick heavily. Being close to natural gas lines or LNG drops tips the scale toward natural gas. Businesses near refineries or out at sea might gain from oil feeds. We’ve advised clients in Europe where pipeline access slashed logistics costs by 35% for natural gas users.

Cost-Benefit Analysis for Industries

The full ownership cost covers fuel rates plus upkeep, meeting emission rules, how it performs over time, and room to grow. Okay Energy crafts custom engineering that fits client setups. We handle full design and build services. This lets companies match their energy tools to future plans.

Conclusion

Selecting between natural gas and oil gasification requires careful consideration of multiple factors, including fuel characteristics, system complexity, environmental impact, and long-term economic performance. Okay Energy’s modern modular systems—from cold LNG vaporizers to LPG skid units—give factory users flexible picks. These systems deliver solid work while watching the budget. Our know-how in engineering aids clients around the world. This spans steel making, power plants, refining, and chemical work.

FAQ

Q: What is the main difference between natural gas and oil gasification?

A: The main difference lies in the feedstock composition—natural gas is methane-based while oil contains heavier hydrocarbons—leading to different syngas outputs, equipment needs, and emissions profiles.

Q: Which is more efficient: natural gas or oil gasification?

A: Generally, natural gas offers higher efficiency due to its cleaner combustion profile, though oil can be efficient at larger industrial scales with proper system design.

Q: Is natural gas always a better choice for industrial energy?

A: Natural gas is not universally superior; selection depends on fuel availability, infrastructure, cost, and specific energy requirements.

Q: What kind of industries use oil-based gasification?

A: Oil-based gasification systems are typically employed in regions lacking natural gas pipelines or in proximity to refineries for power generation or process heating.

Q: Can Okay Energy provide custom solutions based on my industry’s fuel type?

A: Yes, Okay Energy designs tailored gasification systems optimized for either natural gas or oil, based on your operational requirements and regional conditions.